What Does Underground Fiber Optic Cable Look Like?

Introduction:

In today’s digitally connected world, fiber optic cables play a crucial role in transmitting vast amounts of data at lightning-fast speeds. These cables are known for their reliability, security, and superior performance. While most of us are familiar with the concept of fiber optics, have you ever wondered what an underground fiber optic cable actually looks like? In this article, we will delve into the various layers and components making up an underground fiber optic cable.

I. The Outer Protective Layer:

The first layer you will encounter in an underground fiber optic cable is the outer protective layer. This layer is often made of strong materials such as polyethylene or steel, which shield the delicate fiber optic strands from external factors such as moisture, temperature changes, and mechanical stress. The thickness of this layer can vary depending on the specific application and the environment in which the cable is installed.

II. Strength Members:

Beneath the outer protective layer, you will find the strength members. These components are crucial for providing tensile strength to the cable and protecting the underlying fiber optic strands from excessive stretching or twisting. Common materials used as strength members include aramid yarns or fiberglass rods, which are highly resistant to any tensile forces that may arise during cable installation or maintenance.

III. Buffer Tubes:

Moving further inside the cable, we encounter the buffer tubes. These tubes are responsible for housing and protecting the fiber optic strands. Typically, there are multiple buffer tubes within a single cable, each containing a certain number of fibers. The buffer tubes are usually color-coded or numbered for easy identification and maintenance purposes. They offer additional protection against moisture, temperature variations, and physical damage.

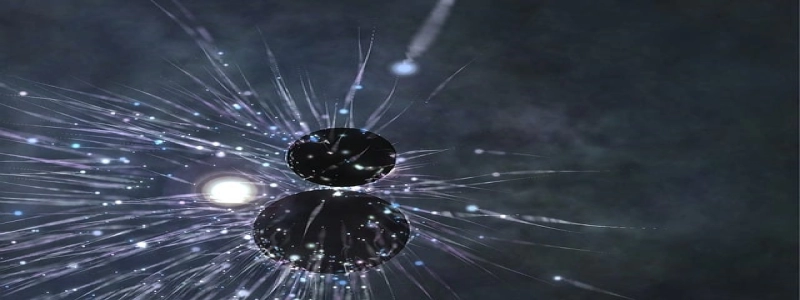

IV. Fiber Optic Strands:

At the core of the underground fiber optic cable lies the fiber optic strands themselves. These strands, often referred to as optical fibers, are incredibly thin, usually the size of a human hair. They are made of high-quality glass or plastic materials that allow for efficient transmission of light signals over long distances. Each strand has the capability to carry enormous amounts of data, making fiber optic technology far superior to traditional copper-based cabling.

V. Central Strength Member:

In larger underground fiber optic cables, a central strength member may be present. This additional component provides an extra layer of protection and stability to the entire cable structure. Similar to the outer strength members, the central strength member is designed to withstand intense tensile forces and prevent damage to the delicate fiber optic strands.

Conclusion:

Underground fiber optic cables consist of multiple layers and components working together to ensure the secure and efficient transmission of data. From the outer protective layer to the fiber optic strands at the core, every element is carefully designed and engineered to withstand various environmental factors and provide optimal performance. Now, next time you encounter a fiber optic cable installation, you will have a better understanding of what lies beneath the surface.