Types of Electrical Wire Connectors

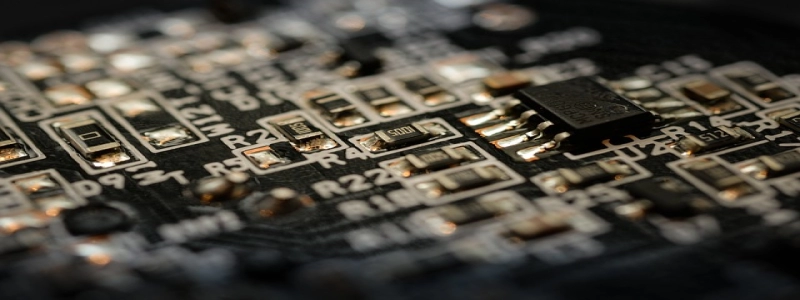

I. Introduction

In any electrical installation, wire connectors play a crucial role in ensuring a safe and reliable connection between electrical conductors. They provide insulation, protection, and facilitate the flow of electricity. This article will explore the different types of electrical wire connectors commonly used in various applications.

II. Twist-On Connectors

Twist-on wire connectors, also known as wire nuts, are one of the most common types of connectors. They are easy to use and require no special tools for installation. Twist-on connectors feature a plastic outer shell with metal threads inside. By twisting the connector clockwise onto the wires, the metal threads create a secure and reliable connection. These connectors are color-coded according to wire size, making it easier to choose the right one for specific applications.

III. Crimp-on Connectors

Crimp-on connectors are widely used in automotive and industrial applications. They require a crimping tool to flatten and secure the connector onto the wires. Crimp-on connectors come in various shapes and sizes, including butt connectors, spade terminals, ring terminals, and bullet connectors. They offer a more dependable and permanent connection compared to twist-on connectors.

IV. Push-In Connectors

Push-in connectors are becoming increasingly popular due to their simplicity and efficiency. These connectors feature multiple contact points that securely hold the wires in place when inserted. They eliminate the need for twisting or crimping, making them a suitable choice for quick and easy installations. Push-in connectors are commonly used in residential and commercial wiring systems.

V. Terminal Blocks

Terminal blocks are used when there is a need to connect multiple wires together. They consist of a strip of metal with screws or clamps that hold the wires in place. Terminal blocks allow for easy removal and reconnection of wires when needed. They are commonly found in electrical panels, control cabinets, and other industrial applications.

VI. Heat Shrink Connectors

Heat shrink connectors provide an added level of protection to wire connections. These connectors are lined with a thermally activated adhesive, which melts when heat is applied. As the adhesive cools down, it forms a watertight and insulation layer around the wires, preventing water, dirt, and corrosion from damaging the connection. Heat shrink connectors are commonly used in outdoor and underground installations.

VII. Conclusion

Selecting the right type of electrical wire connectors is essential for a safe and reliable electrical system. Whether it is a simple residential installation or a complex industrial project, understanding the different types of wire connectors can help ensure proper connections and prevent electrical hazards. From twist-on connectors to heat shrink connectors, there is a wide range of options available to suit various applications.