How to Make Fiber Optic Cable

Introduction:

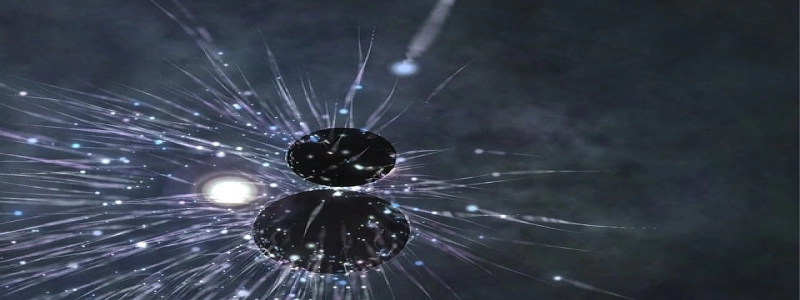

Fiber optic cables have revolutionized the field of telecommunications and data transfer due to their high transmission capacity and speed. Through the use of thin, flexible glass or plastic fibers, these cables transmit information in the form of light signals. In this article, we will provide a step-by-step guide on how to make fiber optic cables.

I. Gathering the Materials

Before starting the cable-making process, ensure you have all the necessary materials. These include:

1. Optical fibers: Acquire glass or plastic fibers that are suitable for transmitting light signals.

2. Cable jacketing material: Choose a protective sheath that is durable and can withstand environmental conditions.

3. Connectors: Obtain connectors that match the type of optical fibers you have.

4. Epoxy and epoxy curing agent: You will need epoxy and its curing agent to fix the fibers into the connectors securely.

II. Preparing the Optical Fibers

1. Measure the length: Determine the desired length of the fiber optic cable and cut the optical fibers accordingly, allowing for a few extra inches.

2. Remove outer coating: Use a precision fiber optic stripper to remove the outer coating from the fibers.

3. Clean the fibers: Using lint-free wipes and fiber optic cleaning solution, thoroughly clean the bare fibers to ensure optimal transmission.

III. Fiber Splicing and Connectorization

1. Strip the protective coating: On both ends of the fibers, strip off a small portion of the protective coating, exposing the bare fibers.

2. Clean the stripped fibers: Clean the bare fibers again to remove any debris or contaminants.

3. Fusion splicing: If you want to join multiple fibers together, use a fusion splicing machine to fuse the fibers permanently. This process ensures minimal loss of light and maintains the integrity of the signal.

4. Connectorization: For individual fibers, carefully insert them into the connectors and secure them in place using epoxy. Mix the epoxy and its curing agent according to the manufacturer’s instructions and apply a small amount to the connectors.

IV. Jacketing and Final Assembly

1. Slide the protective jacket: Slide the cable jacketing material over the bare fibers, covering them completely.

2. Secure the jacket: Use cable ties or heat shrink tubing to secure the jacketing material in place.

3. Test the cables: Use a fiber optic cable tester to ensure the cables transmit light signals effectively without any interruptions.

4. Coil and package: Coil the finished fiber optic cables neatly and package them for storage, transportation, or installation.

Conclusion:

By following these steps, you can make your own fiber optic cables. However, it is essential to remember that working with fiber optics requires precision and expertise. If you are not confident in your skills, it is recommended to seek professional assistance. Fiber optic cables play a crucial role in our modern world, enabling high-speed communication and data transfer, and understanding the process of making them can deepen our appreciation for this advanced technology.