Ethernet Temperature Controller

Introduction:

Ethernet temperature controllers are devices used to control and monitor temperatures remotely through an Ethernet connection. These controllers offer a convenient way to manage temperature settings in various applications, including industrial processes, manufacturing facilities, and laboratory environments.

I. What is an Ethernet Temperature Controller?

An Ethernet temperature controller is a device that uses Ethernet technology to connect to a network and control temperature parameters. It typically consists of a temperature sensor, a control unit, and an Ethernet interface. The temperature sensor measures the temperature, while the control unit processes the data and adjusts the temperature accordingly.

II. Key Features and Benefits:

1. Remote Access:

One of the main advantages of an Ethernet temperature controller is the ability to access and control it remotely. With an Ethernet connection, users can monitor and adjust temperature settings from anywhere with an internet connection. This remote access facilitates real-time monitoring and enables immediate adjustments if required.

2. Precise Temperature Control:

Ethernet temperature controllers are known for their precise temperature control capabilities. These devices can maintain temperature within tight tolerances, ensuring consistency and reliability in temperature-sensitive processes. This level of control is crucial in industries such as pharmaceuticals, food processing, and scientific research.

3. Data Logging and Analysis:

Ethernet temperature controllers often feature built-in data logging capabilities. They can record temperature data at regular intervals, allowing users to analyze temperature trends over time. This data logging functionality is useful for quality control, process optimization, and tracking temperature fluctuations.

III. Applications:

Ethernet temperature controllers find applications in various industries and environments, including:

1. Industrial Processes:

In industrial settings, maintaining optimum temperatures is crucial for efficient and safe operation. Ethernet temperature controllers are used to regulate temperature in equipment such as reactors, ovens, and furnaces. They ensure process stability, preventing overheating or underheating that could lead to product defects or equipment failure.

2. Manufacturing Facilities:

Manufacturing processes often require precise temperature control for optimal results. Ethernet temperature controllers are used in manufacturing industries to regulate temperature during various stages of production. This ensures consistent product quality and reduces the likelihood of manufacturing defects.

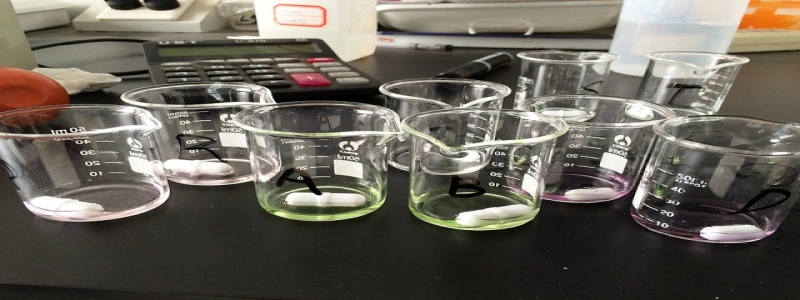

3. Laboratory Environments:

Laboratories dealing with research, testing, and experimentation often have critical temperature requirements. Ethernet temperature controllers are employed to control environmental conditions in these environments, ensuring accurate data collection and maintaining the integrity of experiments.

IV. Conclusion:

Ethernet temperature controllers offer a convenient and efficient way to control and monitor temperatures remotely. With their precise temperature control capabilities and data logging functionality, they contribute to enhanced efficiency, increased productivity, and improved quality control in various industries. Whether it is industrial processes, manufacturing facilities, or laboratory environments, Ethernet temperature controllers play a vital role in maintaining optimal temperatures for reliable operations.