Industrial Wireless Ethernet Bridge

I. Introduction

Industrial wireless Ethernet bridges are essential components in modern industrial settings. They provide a seamless and reliable wireless connection between Ethernet networks in order to enable data transmission and communication between different devices. This article aims to provide a detailed explanation of industrial wireless Ethernet bridges and their significance in industrial environments.

II. What is an Industrial Wireless Ethernet Bridge?

An industrial wireless Ethernet bridge is a device that allows the integration of wired Ethernet networks with wireless networks. It acts as a link between two or more networks, facilitating the seamless transfer of data packets between them. These bridges are specifically designed for use in industrial settings and are characterized by their superior reliability and robustness.

III. Importance of Industrial Wireless Ethernet Bridges

1. Improved Connectivity: By utilizing wireless technology, industrial wireless Ethernet bridges eliminate the need for physical connections between devices, enabling greater flexibility in network layout and device placement. This improved connectivity enhances overall operational efficiency in industrial environments.

2. Cost-Effectiveness: Implementing wired connections in industrial settings often involves significant expenses, such as labor costs for laying cables and maintenance expenses. Industrial wireless Ethernet bridges eliminate these costs, offering a cost-effective solution for network expansion and connectivity.

3. Enhanced Scalability: Traditional wired networks can be challenging to expand or modify in industrial environments due to physical limitations. Industrial wireless Ethernet bridges overcome these limitations by allowing for easy network expansion and scalability without the need for additional wiring.

4. Increased Mobility: Industrial wireless Ethernet bridges enable mobility within industrial facilities. Wireless devices can be easily moved around the premises without the need for reconfiguration or disruption to the network. This flexibility enhances productivity and efficiency in industrial operations.

5. Reliable Data Transmission: Industrial wireless Ethernet bridges are built to withstand harsh environmental conditions commonly found in industrial settings, such as extreme temperatures, vibrations, and electromagnetic interference. These devices ensure uninterrupted and reliable data transmission, critical for the smooth operation of industrial processes.

IV. Key Features of Industrial Wireless Ethernet Bridges

1. Long Range: Industrial wireless Ethernet bridges offer a long-range wireless connection, allowing for seamless communication across large industrial facilities. This range ensures connectivity even in expansive and challenging environments.

2. High Speed and Throughput: These bridges employ advanced wireless technologies, such as Wi-Fi, to provide high-speed data transmission and support high throughput applications. This enables real-time monitoring and control, essential for industrial automation processes.

3. Security: Industrial wireless Ethernet bridges incorporate robust security mechanisms to protect sensitive data transmitted over the network. Encryption protocols and authentication methods ensure the confidentiality and integrity of the data, preventing unauthorized access.

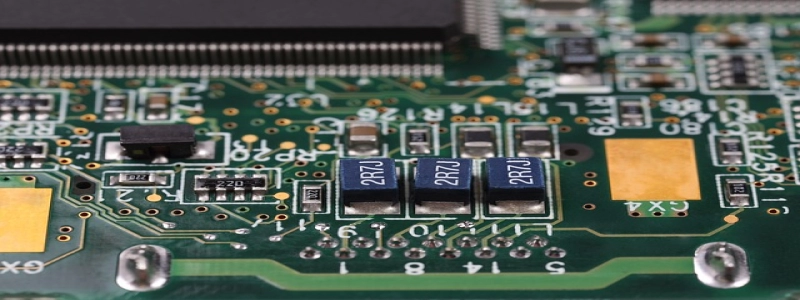

4. Industrial-Grade Design: Industrial wireless Ethernet bridges are designed to withstand harsh industrial environments. They are built with rugged casings, often rated for IP67 protection against dust and water ingress. Some models also feature industrial certifications, like ATEX, for hazardous environments.

V. Applications of Industrial Wireless Ethernet Bridges

1. Industrial Automation: These bridges play a crucial role in enabling wireless connectivity in industrial automation systems. They allow for the seamless integration of various devices, such as PLCs, SCADA systems, and sensors, enabling efficient and real-time control of industrial processes.

2. Remote Monitoring: Industrial wireless Ethernet bridges facilitate remote monitoring of critical infrastructure in industries, such as oil and gas, energy, and transportation. They enable real-time data transmission from remote locations, improving operational efficiency and reducing maintenance costs.

3. Wireless Sensor Networks (WSNs): Industrial wireless Ethernet bridges are essential for the deployment of WSNs in industrial settings. They enable wireless communication between sensor nodes and enable the collection of data for analysis and decision-making.

VI. Conclusion

Industrial wireless Ethernet bridges are vital components in modern industrial settings, providing numerous benefits such as improved connectivity, cost-effectiveness, scalability, and mobility. With their robust design and advanced features, these bridges are instrumental in fostering efficient and reliable data transmission, critical for industrial automation and remote monitoring applications. As industrial environments continue to evolve, the significance of industrial wireless Ethernet bridges is expected to further grow.