I. Introduction to Diode Laser Cutter

A. Definition of diode laser cutter

B. Brief history of diode laser cutter

II. Advantages of Diode Laser Cutter

A. High precision cutting and engraving

1. Ability to cut intricate designs with great accuracy

2. Ideal for creating detailed engravings on various materials

B. Versatility in materials

1. Capable of cutting and engraving various materials such as wood, plastic, and metal

2. Wide range of applications in industries such as signage, jewelry, and fabric

C. Efficiency and speed

1. Diode laser cutter operates at high speeds, resulting in time-saving production processes

2. Efficient energy consumption, reducing operational costs

III. How Does Diode Laser Cutter Work?

A. Principle of laser technology

1. Conversion of electrical energy into light energy

2. Focusing of laser beam for cutting or engraving purposes

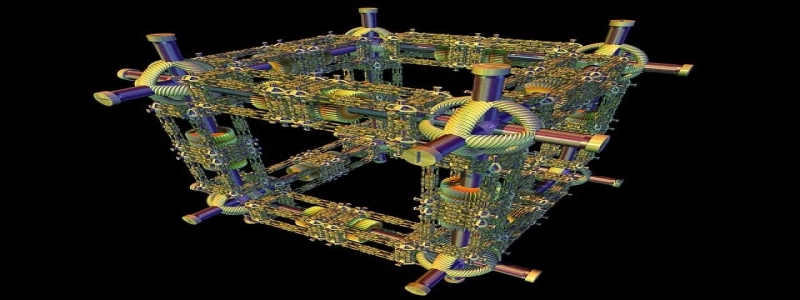

B. Components of a diode laser cutter

1. Semiconductor diode

2. Optics system

3. Cooling system

4. Control software and interface

C. Process of cutting and engraving

1. Preparation of materials and file

2. Setting parameters such as power, speed, and frequency

3. Operation and control of the diode laser cutter

4. Finishing and post-processing of the cut or engraved materials

IV. Safety Precautions when Using Diode Laser Cutter

A. Proper training and certification

B. Wearing protective gear (goggles, gloves)

C. Regular maintenance and inspections

D. Proper ventilation in the working area

V. Conclusion

A. Recap of the advantages and applications of diode laser cutter

B. Future trends and advancements in diode laser cutter technology

C. Importance of incorporating diode laser cutter in modern industries.