Laser Diode Engraving

I. Introduction

A. Definition of Laser Diode Engraving

B. History and evolution of laser diode technology

II. Working principle of laser diode engraving

A. Explanation of the laser diode

B. Comparison with other engraving techniques

III. Applications and advantages of laser diode engraving

A. Engraving on various materials

B. Precision and accuracy

C. Speed and efficiency

D. Versatility and customization

E. Cost-effectiveness

IV. Precautions and safety measures

A. Eye protection and laser safety glasses

B. Proper ventilation and workspace organization

C. Handling and maintenance of laser diode engraving machines

V. Future developments and possibilities

A. Advancements in laser diode technology

B. Integration of laser diode engraving in various industries

C. Potential for increased automation and productivity

VI. Conclusion

I. Introduction

Laser diode engraving is a cutting-edge technique that utilizes laser technology for precise and detailed engraving on various materials. The process involves the use of a laser diode, a small semiconductor device that emits laser light when an electric current passes through it.

The history of laser diode technology can be traced back to the early 1960s when the first laser diode was developed. Over the years, there have been significant advancements in laser diode technology, making it a popular choice for engraving due to its efficiency, versatility, and cost-effectiveness.

II. Working principle of laser diode engraving

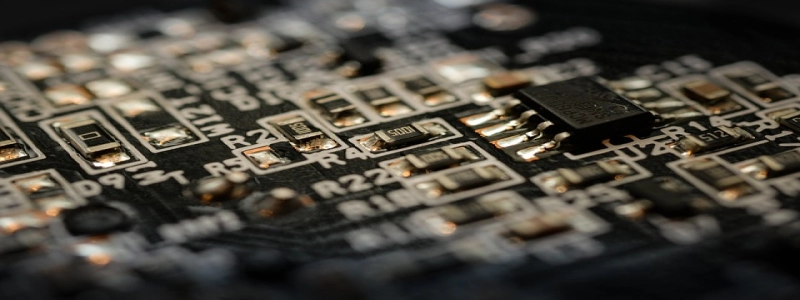

A laser diode consists of a tiny diode, often made from gallium arsenide or other similar materials, and emits a coherent beam of light. This light is focused and directed towards the surface of the material to be engraved. As the laser light interacts with the material, it vaporizes or melts it, leaving behind a permanent mark or engraving.

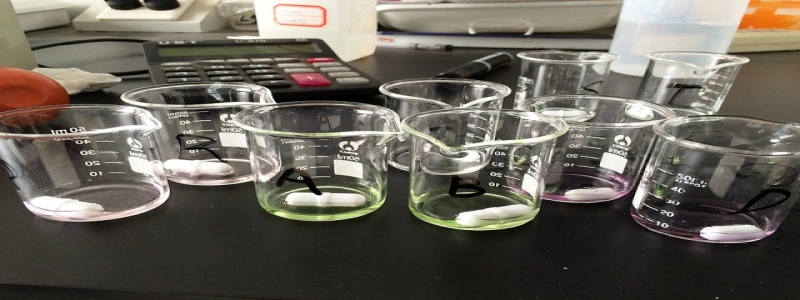

Compared to other engraving techniques such as mechanical engraving or chemical etching, laser diode engraving offers numerous advantages. It does not require physical contact with the material, resulting in a clean and precise engraving without any distortion. Additionally, it can engrave complex designs and patterns with high accuracy and resolution.

III. Applications and advantages of laser diode engraving

Laser diode engraving finds applications in a wide range of industries, including manufacturing, electronics, jewelry, automotive, and more. It can engrave on materials such as metal, plastic, wood, glass, leather, and even organic materials like food products or textiles.

The advantages of laser diode engraving are multifold. Firstly, it offers unparalleled precision and accuracy, allowing for intricate details and fine lines. Even the most complex designs can be engraved with ease, ensuring a high-quality end product.

Secondly, laser diode engraving is incredibly fast and efficient. It can complete engraving tasks in a matter of seconds or minutes, depending on the complexity of the design. This significantly reduces production time and increases productivity.

Thirdly, laser diode engraving allows for versatility and customization. It can engrave logos, text, serial numbers, barcodes, or even images, providing endless possibilities for personalization and branding.

Moreover, laser diode engraving is a cost-effective solution. It eliminates the need for consumables like engraving bits or chemicals, reducing operational costs. Additionally, the non-contact nature of laser diode engraving minimizes wear and tear on the equipment, resulting in lower maintenance and replacement costs.

IV. Precautions and safety measures

While laser diode engraving offers numerous benefits, it is important to adhere to safety measures to prevent accidents or injuries. Eye protection is crucial, and laser safety glasses should always be worn to protect against potentially harmful laser beams.

Proper ventilation is also essential when using laser diode engraving machines. The process can produce fumes or smoke, depending on the material being engraved, and adequate ventilation helps maintain a safe working environment.

Lastly, handling and maintenance of laser diode engraving machines should be carried out carefully and in accordance with manufacturer instructions. Regular calibration and cleaning are necessary to ensure optimal performance and longevity of the equipment.

V. Future developments and possibilities

The future of laser diode engraving looks promising. Technological advancements are continually being made, leading to more efficient and powerful laser diodes. This will enhance the engraving capabilities and open up new opportunities for applications.

Furthermore, laser diode engraving is poised to become an integral part of various industries. Its ability to engrave on diverse materials and high precision makes it suitable for applications in aerospace, medical devices, consumer electronics, and more.

With increasing automation and robotics, laser diode engraving is expected to become more streamlined and integrated into production lines, further enhancing productivity and reducing human intervention.

VI. Conclusion

Laser diode engraving is a sophisticated engraving technique that offers precision, speed, versatility, and cost-effectiveness. Its applications span across various industries, and the technology is continually advancing.

As laser diode engraving becomes more commonplace, it is essential to prioritize safety measures to protect against potential hazards. With ongoing technological improvements, laser diode engraving will continue to evolve and find new applications, revolutionizing the field of engraving.