Cutting Clear Acrylic with Diode Laser

Introduction:

Clear acrylic is a popular material used for various applications such as signage, display cases, and decorative items. Cutting acrylic accurately and efficiently is a crucial process in many industries. In recent years, diode lasers have gained popularity for their versatility and precision. In this article, we will discuss how to cut clear acrylic using a diode laser, along with the benefits and considerations.

I. Understanding Diode Lasers:

A. Diode lasers are a type of solid-state laser that use a semiconductor as the laser medium.

B. They emit a concentrated beam of light with a specific wavelength that can be adjusted based on the application.

C. Diode lasers are compact, efficient, and cost-effective, making them suitable for small-scale cutting operations.

II. Benefits of Cutting Clear Acrylic with a Diode Laser:

A. Precision: Diode lasers offer high accuracy and can achieve intricate designs and smooth edges.

B. Versatility: The wavelength of diode lasers can be adjusted to suit different thicknesses of clear acrylic.

C. Speed: Diode lasers can cut acrylic quickly, increasing productivity and reducing production time.

D. Minimal Heat: Diode lasers generate less heat during the cutting process, reducing the risk of material distortion or melting.

E. Cost-effective: Diode lasers are affordable compared to other laser cutting options, making them a cost-effective choice.

III. Considerations for Cutting Clear Acrylic with a Diode Laser:

A. Power and Speed Settings: Adjusting the power and speed settings on the diode laser is crucial for achieving clean cuts without damaging the acrylic.

B. Focusing: Ensuring proper focus of the laser beam is important for achieving precise and accurate cuts.

C. Ventilation: Clear acrylic cutting releases fumes that can be harmful, so proper ventilation systems should be in place.

D. Safety Precautions: Diode lasers are powerful tools, and operators must follow safety procedures such as wearing protective eyewear and gloves.

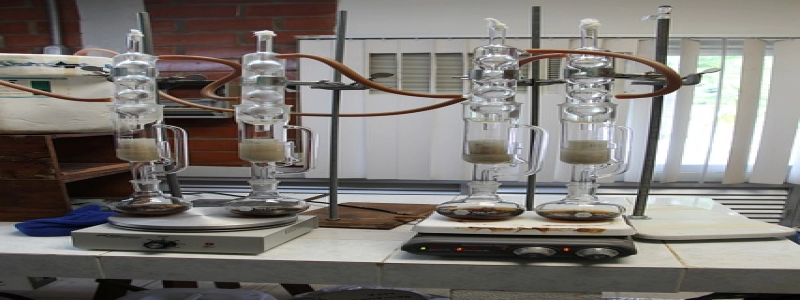

IV. Step-by-Step Guide to Cutting Clear Acrylic with a Diode Laser:

A. Prepare the acrylic sheet by ensuring it is clean and free from any dust or debris.

B. Set the power and speed settings on the diode laser based on the thickness of the acrylic and desired cutting speed.

C. Place the acrylic sheet on the laser cutting bed, ensuring it is secure and flat.

D. Adjust the focus of the laser beam to ensure accurate cutting.

E. Start the laser cutting process, allowing the diode laser to cut through the acrylic sheet.

F. Once the cutting is complete, remove the acrylic sheet from the cutting bed and inspect the cuts for accuracy and cleanliness.

G. Clean the laser cutting area and ensure proper ventilation to minimize fume exposure.

Conclusion:

Cutting clear acrylic with a diode laser offers numerous benefits, including precision, versatility, and cost-effectiveness. By following the proper procedures and considering essential factors, operators can achieve clean and accurate cuts in acrylic sheets. Diode lasers have revolutionized the acrylic cutting process and continue to be a preferred choice for many industries.