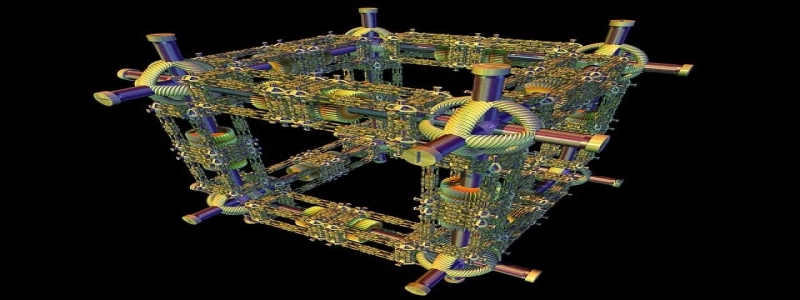

Fiber Optic Cable Cross Section

Introducción:

En este articulo, we will explore the cross-section of a fiber optic cable, which is a vital component of modern communication systems. We will delve into the various layers and components that make up a fiber optic cable, providing a detailed understanding of its structure and functionality.

I. Outer Sheath:

The outer sheath is the first layer of protection for the fiber optic cable. Typically made of a strong and durable material like PVC or polyethylene, it shields the cable from external environmental factors such as moisture, dust, and pests. Additionally, the outer sheath provides added mechanical strength, ensuring the cable’s integrity even under harsh conditions.

II. Strength Members:

Beneath the outer sheath, fiber optic cables are reinforced with strength members. These can be metallic wires or aramid fibers, such as Kevlar, which provide tensile strength and prevent cable elongation. The strength members enhance the cable’s resistance to stretching and bending, safeguarding the delicate fiber optic strands within.

III. Buffer Coating:

The next layer of the fiber optic cable is the buffer coating. It is applied directly over the fiber optic strands and serves as an additional protective layer. Composed of a soft polymer material, the buffer coating not only acts as insulation but also minimizes stress and strain on the fibers during handling and installation.

IV. Fibers:

At the core of the fiber optic cable are the individual fiber strands that carry the optical signals. These strands, each thinner than a human hair, are typically made of silica or plastic. Within each fiber strand, there are two key components: the core and the cladding. The core is the innermost region, through which the light travels. Surrounding the core is the cladding, which has a lower refractive index to reflect the light back into the core, minimizing signal loss.

V. Strength Member:

Within each fiber optic cable, individual fiber strands are bundled together and surrounded by a strength member. This strength member provides additional protection and support to the individual fibers, preventing damage from excessive stresses or external impact.

VI. Jacket:

The final layer of the fiber optic cable is the jacket. Similar to the outer sheath, the jacket is made of a sturdy material such as PVC or polyethylene. It provides another level of protection to the entire cable, shielding it from moisture, chemicals, and physical damage. The jacket also provides added insulation, ensuring the optimal performance of the fiber optic cable.

Conclusión:

Understanding the cross-section of a fiber optic cable is crucial in comprehending its structure and functionality. From the outer sheath to the innermost fibers, each component serves a specific purpose in protecting and transmitting optical signals. By considering the various layers and components, it becomes apparent that fiber optic cables are intricately designed to provide reliable and efficient communication in today’s interconnected world.